In 2019, the global digital twin market was valued at USD $3.8 billion. A great proportion of the industrial sector has already adopted this technology, and the expectation is that the digital twin market will be valued at $26 billion by 2025 (assuming a 38% annual growth rate) as sectors such as healthcare, urban planning, and retail sales explore the possibilities of digital twins as well.

What is a digital twin?

A digital twin is a digital program that represents a virtual model of a real object or system. A digital twin leverages artificial intelligence, the Internet of Things, big data, blockchain, virtual reality technologies, collaborative platforms, APIs, and open standards. These underlying technologies allow a digital twin to be continuously fed by real-world data so that it can effectively and efficiently offer real-time insights about the object’s or system’s present and future performance and problems.

How do digital twins help to repurpose sustainability values?

There is no doubt that digital twins drive companies to be better at innovation and performance. Indeed, hundreds of technical and nontechnical publications illustrate how digital twin technology can be useful for designing, visualizing, monitoring, managing, and maintaining corporate assets more effectively. Moreover, digital twin technologies have allowed several companies to either directly or indirectly repurpose their sustainability values. The idea is that digital twins can virtually help to look beyond the current industrial model of extract, produce, consume, and dispose. Thus, companies and even entire cities have options to shift to a “circular economy” system that considers almost zero production of waste and pollution, keeps products and materials longer within the recycling loop, and helps to regenerate natural systems.

Overall, the deployment of digital twins can contribute to a 20% reduction in global carbon dioxide emissions by 2030. The efficiency in operations also allows companies to readjust the way products and services are made and offered, with the use or reuse of lighter, more durable materials translating into energy savings.

The following cases exemplify how the digital twin technology can bring changes that help create a more sustainable world and make business more successful.

A bid to improve the recycling process of plastics:

Plastics are essential to industries ranging from packaging and textiles to construction, transportation, healthcare, electronics, and many others. In the last 50 years , global production of plastics has increased 20-fold, from 15 million tons to 311 million tons, with only 9% of all plastic produced being recycled. A staggering 91% ends up causing USD $80-$120 billion per year lost to the global economy while producing major environmental damages.

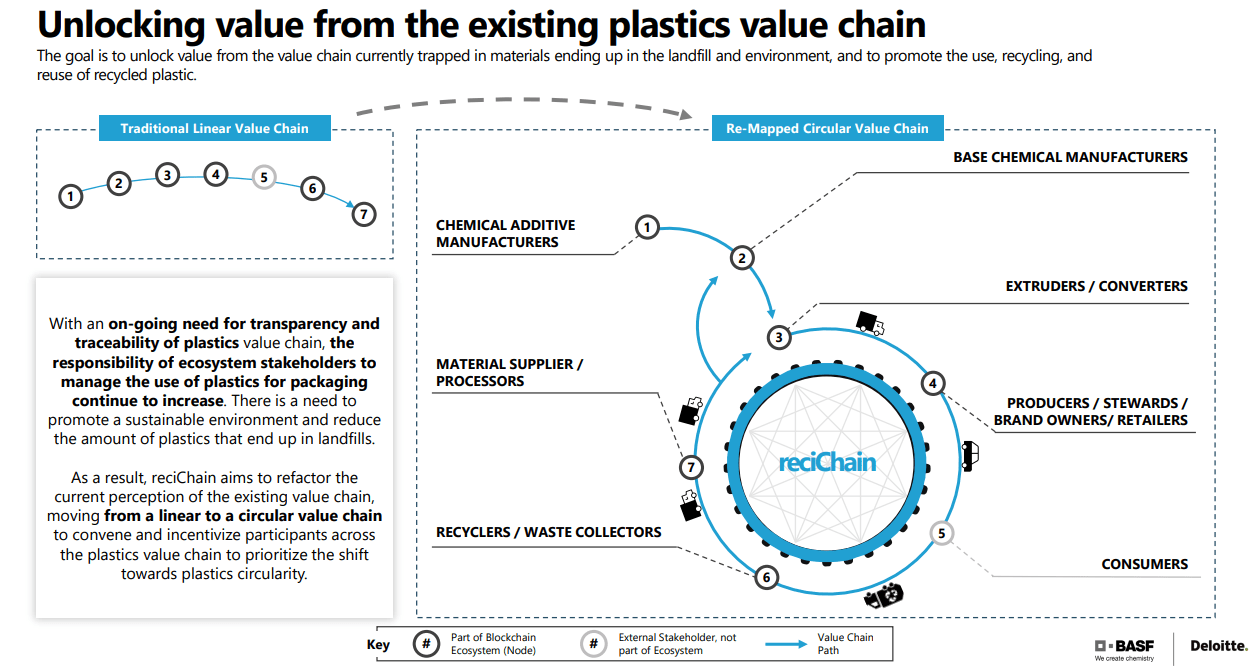

In response, BASF is developing its blockchain-enabled platform reciChain to improve traceability of recycled plastics and is running major pilot test centers in both South and North America. The project involves the use of digital twins to enable the physical and digital tracking of recycling material. BASF has partnered with Optel and Security Matters. Both companies have developed unique barcoding systems that can withstand manufacturing and recycling processes without any alteration of recycled materials. Using digital tracers, these barcodes aim to capture all information to authenticate sustainability claims and make the sorting process more accurate. With such technology in place, BASF is expecting to systematically unlock the value of recycling materials that often end up in landfills.

Optimizing the property of materials and improving the performance of energy storage:

Industries involved in the production of cars, trains, and aircraft often invest in pursuing innovative solutions that can address the challenge of finding strong and lightweight materials that can help to reduce energy consumption as well as material components that will increase the capacity to store energy more efficiently.

Optimization of materials by trial and error is time and money consuming, and there is no guarantee that the materials will meet the required specifications. To address these challenges, Math2Market has developed GeoDict, a digital twin software program that provides real-time simulations of a variety of material properties. Images are acquired from CT scans, electron microscopy images, or virtual generation of realistic 3D-microstructures. Once the virtual model is synced with the raw material, the digital twin can model the internal geometry and structure of nonwoven fabrics, foams, ceramics, composites, and even the internal composition of batteries and fuel cells. Thus, digital twins can provide a unique understanding of the physical properties of materials, leading to better solutions.

Helping to reduce carbon emissions in urban areas:

British company Integrated Environmental Solutions (IES) has recently developed the Intelligent Communities Lifecycle (ICL). This environmental digital twin technology reduces carbon emissions of buildings and cities worldwide. ICL bridges the gap between the real and virtual worlds to enable energy-efficient design and continuous optimization by incorporating real-world operational data, which keeps digital-twin accurate. Thus, buildings can provide information on potential anomalies that were previously unlikely to be captured.

One of the current users of ICL technology is the Nanyang Technological University (NTU) in Singapore. The ICL technology covers the whole of NTU’s 250-hectare campus and the adjoining 50-hectare JTC Corporation CleanTech Business Park, with more than 200 buildings on site covering a 1.1 million square meter floor area.

The intelligent community design master planning model is 91% accurate for total and 97% for chiller energy consumption. ICL has helped to unleash 10% energy savings (USD $3.9 million per year) and locked the annual emissions of 8.2 kilotons of carbon. ICL also helped to visualize potential savings based on more efficient technologies related to building envelope, lighting and occupancy sensors, plug load management, and high-performing optimized chillers, which demonstrated an additional 31% average of energy savings (USD $4.7 million).

Concluding remarks:

Companies are gradually adopting digital twins to manage their most critical assets. In return, digital twins are helping monitor and identify ways to become more efficient, prevent downtimes, and even plan for the future. As in the case of BASF, digital twins can inform decisions on whether to reuse, recondition, recycle, or scrap plastic products along with where to collect them from.

Digital twins also offer the possibility of improving and selecting the right materials for manufacturing purposes targeting energy savings or simply being more efficient at the storage of renewable energy. And ICL demonstrates that digital twins can indeed help companies to repurpose their sense of sustainability and take it to a plausible level.

In the end, development with a good sense of sustainability is key for corporations to thrive while limiting their environmental footprint.